Rotary locks or sluices or sometimes even addressed as Rotary valves.

We manufacture and repair Rotary Locks using our expertise in increasing the life of machinery. We have carefully drafted this technology and today we do this for world leaders in cement industry.

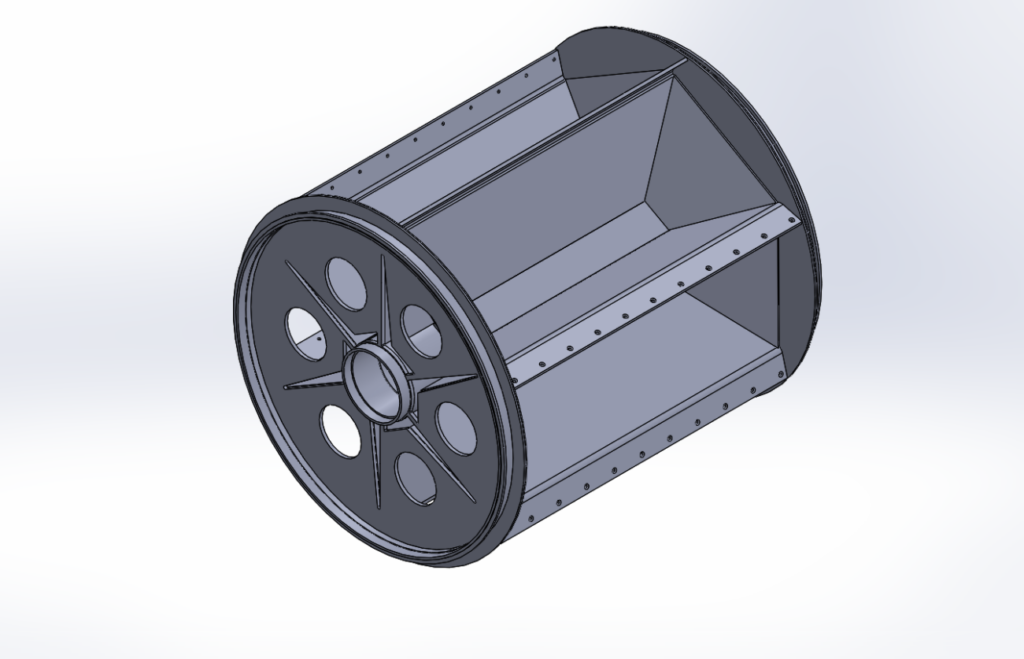

A standard rotary lock consists of housing , rotor area or sometimes called as bucket wheel and the shaft.

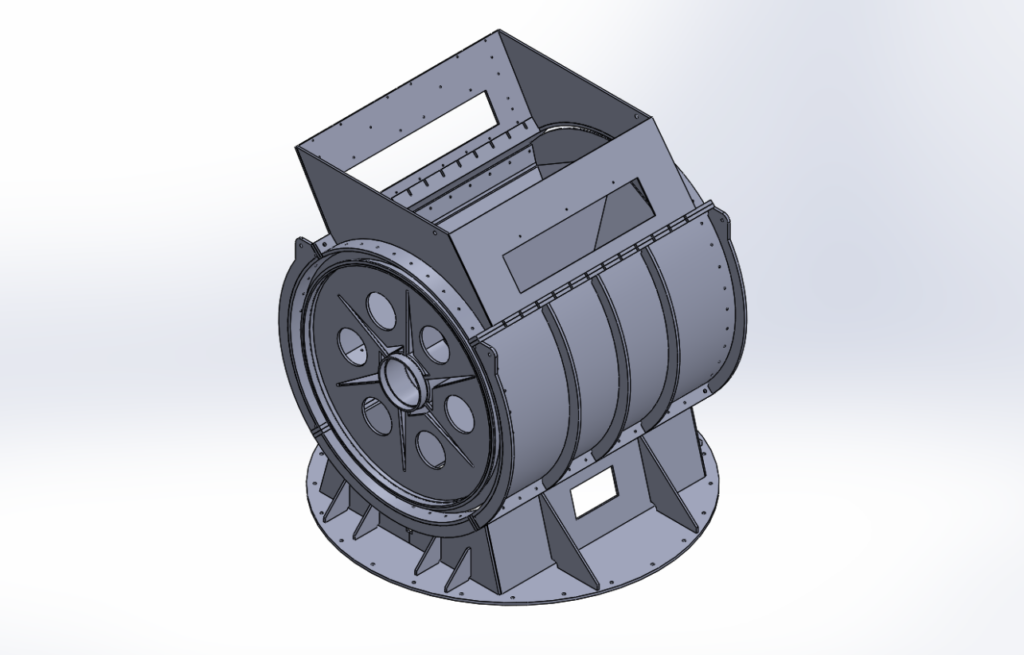

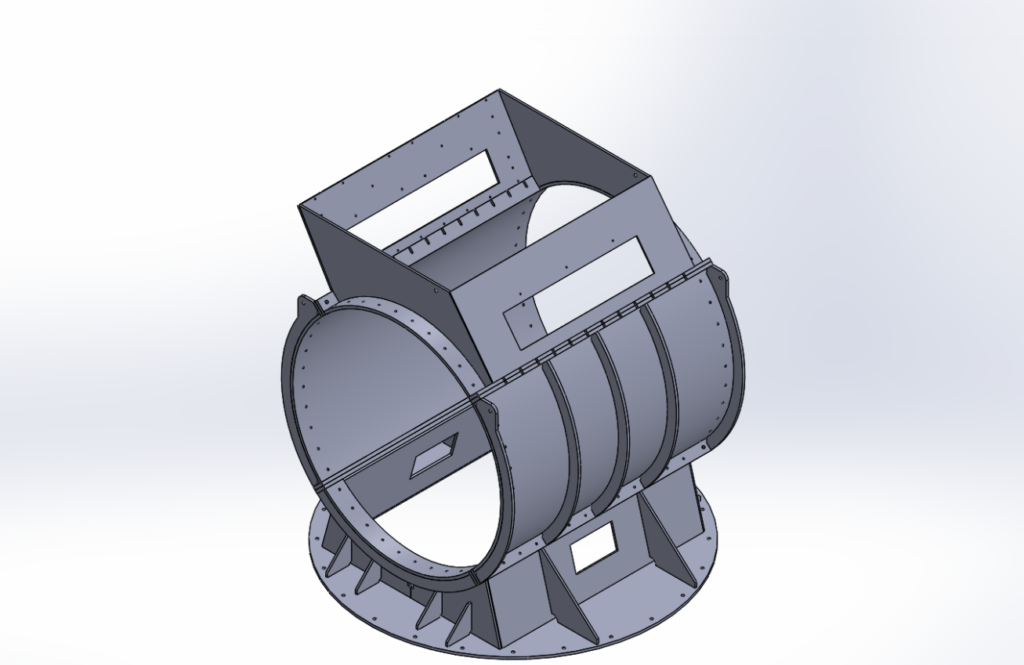

Complete rotary lock manufacturing

Rotary Housing

Bucket wheels or Rotors

Choosing a MEC rotary valve in abrasive applications provides you with a longer lasting, more efficient and reliable running rotary valve.

By protecting all areas exposed to wear, leaves you with smooth running rotary valves in the long run. The housing is often exposed to the highest degree of wear in a rotary valve. We use our Complex carbide liners in the inner diameter of the housing. It ensures best possible wear protection.

After installation the housing are diamond grinded to the required tolerance.

Benefits by using wear protected rotary valves from MEC

● Longer durability

● Less maintenance

● Fewer unexpected stops

● More stable and accurate flow

● Better efficiency

● Lower energy consumption

Open rotor rotary valves can also have wear on the side discs. Side disc can also be protected using the same method. For wear protection of the Rotor, we use niobium-based carbide overlay plates.