The primary idea behind any kind of automation is to improve efficiency repeatability and quality of work done. We have tied up with global leaders in welding automation to provide you with best of the solutions in this.

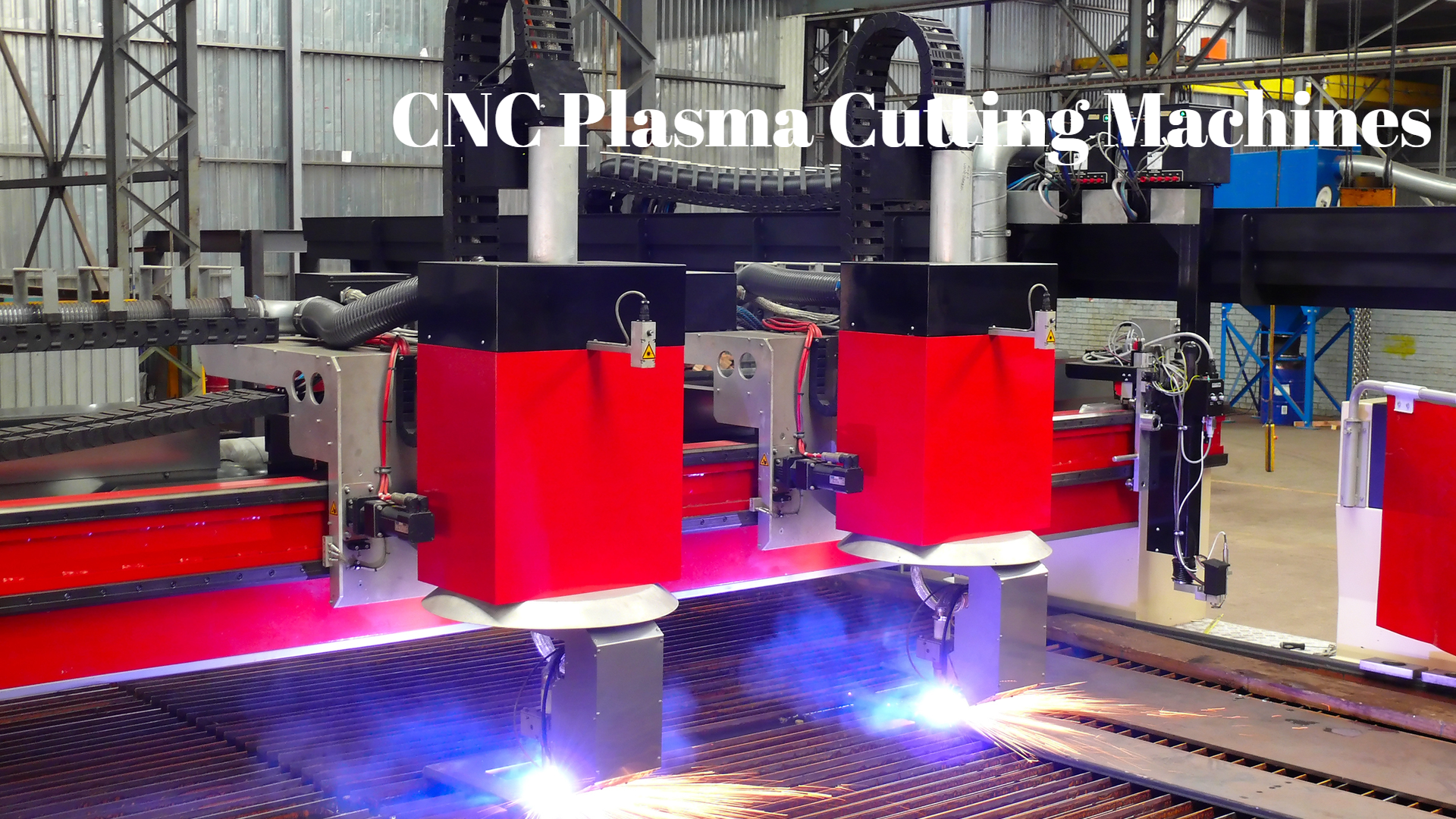

Our comprehensive range of CNC cutting machines is today revolutionizing the cutting industry. Our machines are built by using parts from world leaders like Hypertherm, Kjellberg, IHT Automation and Ecklemann

Frontiers of research

Mechanical engineers are constantly pushing the boundaries of what is physically possible in order to produce safer, cheaper, and more efficient machines and mechanical systems. Some technologies at the cutting edge of automation engineering are listed below.

Micron-scale mechanical components such as springs, gears, fluidic and heat transfer devices are fabricated from a variety of substrate materials such as silicon, glass and polymers like SU8. Examples of MEMS components are the accelerometers that are used as car airbag sensors, modern cell phones, gyroscopes for precise positioning and microfluidic devices used in biomedical applications.

Friction stir welding, a new type of welding, was discovered in 1991 by The Welding Institute (TWI). The innovative steady state (non-fusion) welding technique joins materials previously un-weldable, including several aluminum alloys. It plays an important role in the future construction of airplanes, potentially replacing rivets. Current uses of this technology to date include welding the seams of the aluminum main Space Shuttle external tank, Orion Crew Vehicle test article, Boeing Delta II and Delta IV Expendable Launch Vehicles.